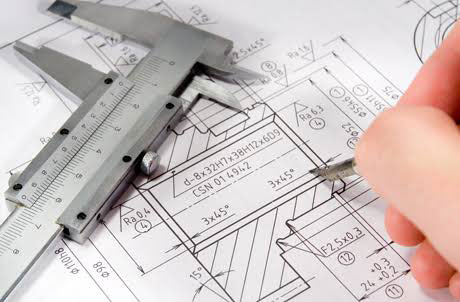

Part Design & Development

In the realm of part design and development precision meets creativity to craft components that are not just functional but also aesthetically pleasing. This intricate dance between engineering ingenuity and aesthetic finesse defines the essence of our approach. Join us on a journey were every detail matters, each part is a testament to the seamless fusion of form and function.

Manufacturing of Precision Press Parts

In the dynamic landscape of manufacturing our commitment to excellence stands tall, particularly in the precision realm of press parts. We orchestrate a symphony of advanced techniques and seasoned craftsmanship to deliver components that embody precision at its zenith. Our manufacturing processes are a fusion of technological innovation and meticulous attention to details. From initial step to final product every step is calibrated for accuracy.

Tape & Reel Packaging of RF Shield Parts

As guardians of signal integrity, these components demand not just excellence but a packaging solution that ensures their pristine conditions. Our reel and tape packaging process is a seamless fusion of protective engineering and logistical finesse. Each RF shield part is meticulously nestled in its designated space, shielded from environmental factors that could compromise its functionality. Reel and tape packaging not only secures the integrity of the component but also facilitates efficient handling during assembly and integration.

We offer you the alternative to minimize production time and costs gives you competitive advantage in the mass production of products. Tape & reeling your electronic or mechanical parts can help you transition from manual to automatic placement during the assembly or surface mount technology (SMT) process, achieving faster throughput and saving you significant labour costs.

Sheet Metal Stamping & Pressing

A raw sheet metal piece takes on a new dimension through our stamping and pressing expertise. In the symphony of manufacturing, every press and stamp resonates with the commitment to craft sheet metal into new masterpiece of form and function. Our sheet metal stamping and pressing process shaping raw material into intricate designs with a precision that’s second to none. From prototyping to mass production each stroke of the press is a testament to our dedication to excellence.

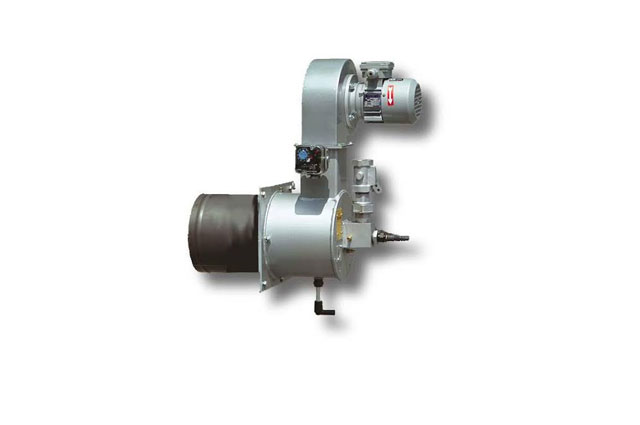

Assemblies & Sub-Assemblies

We specialize in orchestrating the delivery of meticulously crafted components, ensuring that each piece seamlessly integrates into the larger assembly, driving efficiency and precision. With a focus on quality control and timely delivery, we become an extension of your production line, enhancing reliability and reducing downtime. From intricate sub-assemblies to robust mechanical components, our supply chain is a conduit of excellence. Every piece we deliver is a testament to our dedication to precision, reliability, and the seamless flow of your manufacturing operations.

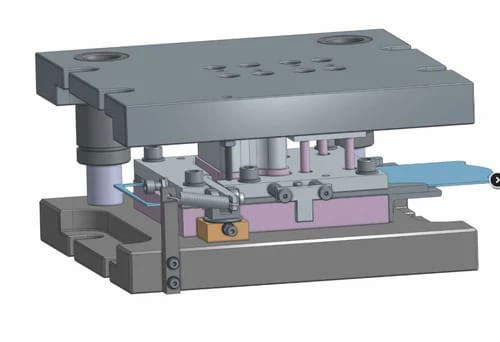

Tool Design & Manufacturing

From conceptualization to the final blueprint, we meticulously tailor each tool to meet the unique demands of its intended applications. Whether its cutting – edge dies, forming dies or specialized jigs & fixtures.

Light Fabrication

Our expertise in light fabrication transcends the ordinary, bringing forth a spectrum of meticulously crafted solutions tailored to meet your unique needs. Each fabrication project, whether its sleek structural component or an intricate design element, is approached with the same commitment to excellence. Our state of the art facilities and skilled workmen converge to seamlessly bring your ideas to life. Whether its Al (Aluminium), SS (Stainless steel), MS (Mild steel) or other materials, our fabrication process ensures that every piece is just not fabricated; its engineered to elevate your projects.