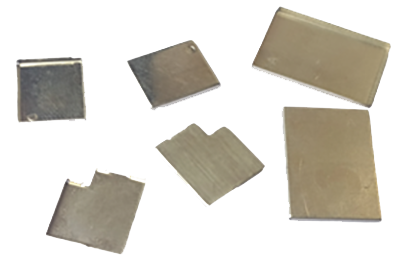

EMI/EMC/RF Metal Shields Samples

M/s. Sahyadree Engineering Works (SEW) Leading Manufacturer for Customized EMI/EMC/RF Metal Shields

Welcome to Sahyadree Engineering Work (SEW), specialized in Development & supply of PCB mounted EMI/EMC/RF shields in reel & tape in vacuum packing for automatic pick & place (APP) machine for the electronics industry.

We have in-house tool room, press shop & reel & tape packaging facility etc. under one roof which is meeting requirement for end to end solution for supply of such PCB mounted shields.

We develop & deliver high-quality, precision-engineered shields based on customize drawings, ensuring a perfect fit and function performance.

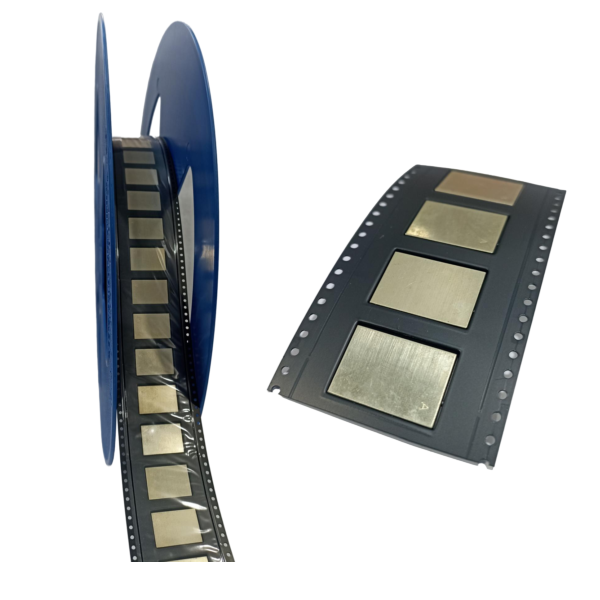

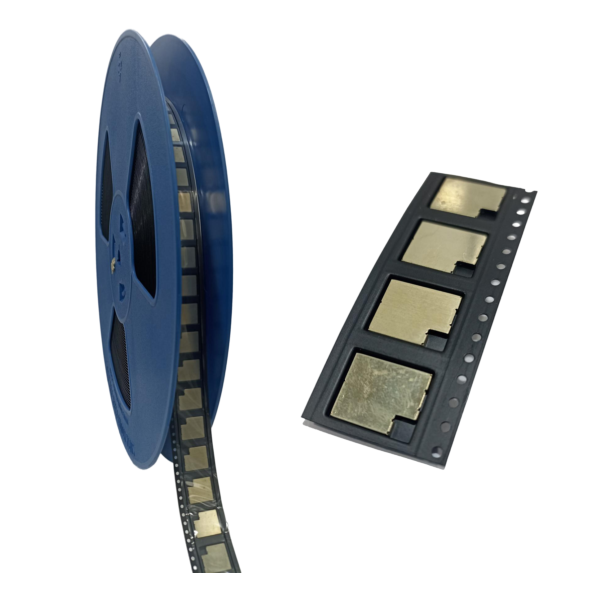

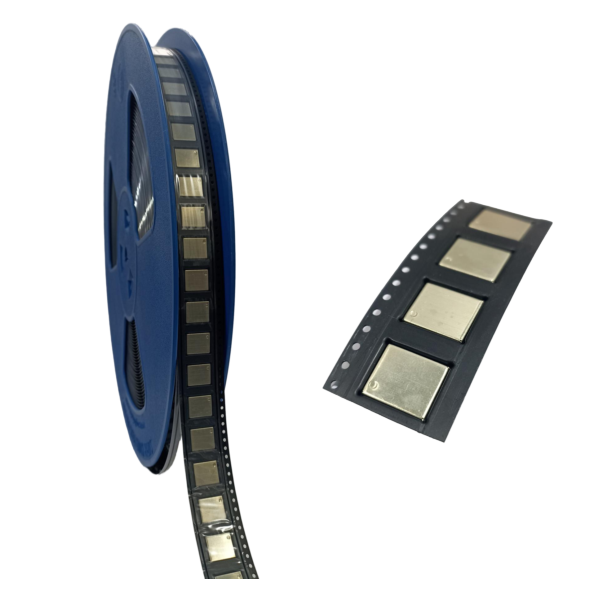

Surface Mount Shields (SMS) offer a highly reliable, cost effective, off-the-shelf Board Level Shielding solution for most surface mount shielding applications. Our SMS are supplied in tape & reel packaging and are suited for any volume application including automated pick and place m/c operations. SEW offers the large selection of off-the-shelf mass produced shields in the industry today. SEW developed & supplied millions of PCB mounted shields.

Our advanced manufacturing facilities and expert team meet stringent quality standards with zero defect supplies. SEW provides tailored shielding solutions that protect your components from electromagnetic interference, ensuring reliability and longevity.

| Raw Material | Nickel Silver, Phosphor Bronze, Cupronickel, Tinplate, Copper, or according to your requirement |

|---|---|

| Surface Finish / Treatment | Tin Plated, Silver Plated, Gold Plated, etc |

| Thickness | According to customer requirements |

| Sample Availability | Proto samples available within 2 weeks |

| Type of Packing | In the Reel and Tape Form For Automatic Pick & Place Machine, Blister, Plastic Bag, VCI Bags, Moisture Barrier Bags (MBB) etc. according to customer requirement. |

| EU directives / Regulations | REACH & ROHS compliance |

| Test | Solder ability properties |

Reel and Tape packaging machine

Streamline your production process with our reliable tape and reel packaging services. Ideal for electronic components such as surface mount devices (SMDs), our precision-engineered tape and reel solutions ensure secure and efficient handling during manufacturing and assembly.

Benefits:

Efficiency: Facilitates automated pick-and-place operations, reducing assembly time.

Protection: Safeguards components from damage during handling and transportation.

Compatibility: Customizable options to fit various component sizes and types.

Quality Assurance: Adheres to industry standards for consistent performance.

BMR251-936

BMR271-016

BMR251-924

Vacuum Packaging Machine

Vacuum Packaging in MBB

EMI/EMC/RF shield are supplied in vacuum packing in reel & tape form.

Vacuum packing removes oxygen from the primary packaging using suction. Once oxygen is removed from the package, it's completely sealed off from exterior .Ensure the integrity and longevity of your electronic components with our specialized vacuum packaging machines. This is done by using moisture sensitivity bag Designed to meet the stringent requirements of electronics and automobile manufacturing, our machines provide a reliable solution for preserving components during storage and transportation.

Moisture Barrier Bags (MBB) are used for vacuum packing

Key Features:

ESD Protection: Safeguard sensitive electronic parts from electrostatic discharge (ESD) to prevent damage.

Moisture Barrier: Create a sealed, moisture-free environment to protect components from humidity and oxidation.

Customizable Options: Our vacuum packaging machine comprises of large vacuum chamber which enables machine to accommodate various component sizes and types. (chamber size:465x440x80mm)

Quality Assurance: Compliant with industry standards to maintain product reliability and performance.

Operational Efficiency: User-friendly interfaces and automated processes streamline packaging operations, reducing labour costs and enhancing productivity.

Enquiry Now

FAQ

1) Materials

2) Surface Finish

3) Tolerance

4) Quantity